SPECIAL PROJECT

Line

"LISA"

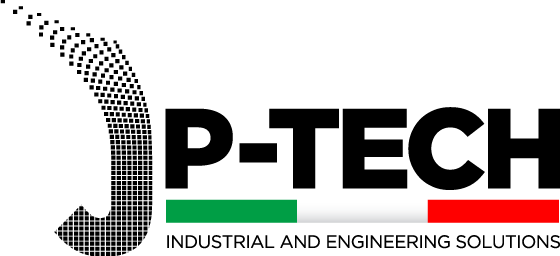

LISA was born from the need of a client company to have an automatic line that would allow:

- Unroll a reel with a rubber band

- Place the primer on one side

- Place a special double-sided adhesive tape and remove the waste

Next step decide whether:

- Wind on bobbins

- Wind on bobbins with interrupted cut

- Cut into blocks

- Cut into blocks with any number of interrupted cuts of your choice

All without interruptions.

Thanks to JP-TECH's study and the application of a special permanent magnet motor, all this was made possible.

Today the line is used to process multiple materials

"LUCY"

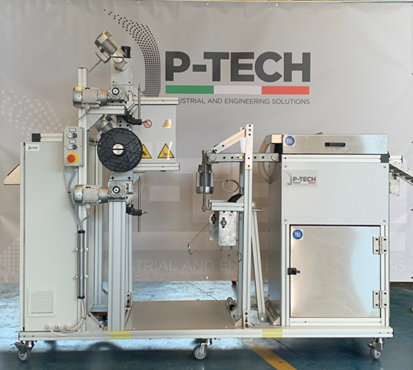

LUCY was born from the search for a machine that could treat, powder and wind a new product patented by an important European group.

The product in question is a silicone master batch cord used to color neutral compounds without the use of powders. Designed to avoid waste and costs for users, it was the ideal project for JP-TECH

The requests, in addition to those listed previously, were: reduced dimensions of the machinery, light machinery, easy to move on multiple lines, double feed, reels weighing between 5 and 10 kg with a maximum waste of 5 grams; Let's not add anything other than that WE SUCCEEDED.

To date, the machinery works on multiple shifts, guaranteeing master batch reels for many companies.

"ELSA"

Compact dimensions and with the possibility of arranging the system with variable layouts.

The line is made up of several primary blocks which are actually four different machines that can also be used as autonomous machines.

The automatic warehouse of the product to be processed is thermostated and can maintain the product at temperature both during heating and cooling.

The filter press, which can work automatically, providing precise information about the status of the product production process.

Trommel complete with cutting and framing unit with integrated system, cooling of the finished product.

The system allows you to work in: manual, semi-automatic, automatic with operator panel, voice module that signals approximately 256 work cycle and emergency by voice and data acquisition system. A series of data and information is available both for the operator and for the quality control laboratory.

The ELSA line is a combination of decades of work experience and construction of products with advanced technology that make it an absolute novelty in the processing of Rubber, Silicone, Viton and other products.

CERTIFIED DESIGN AND CONSTRUCTION